Technique - Recelling a Metabo 6.2547x battery

Word upfront

These kind of practices are not without risk! Know what you are getting yourself into!

Where you read 6.25473 in this article, this also goes (as far as I know) for Metabo:

- 6.25470 and 6.25471 (NiCd 9,6 Volt, 1,4 and 2,0 Ah, just a different amount of cells)

- 6.25473 and 6.25474 (NiCd 12 Volt 1,4 and 2,0 Ah)

- 6.25479 (NiMh 12 Volt 3 Ah)

When it comes down to the costs this is hardly interesting. 10 cells (Panasonic BK300SCE, the E-variant of BK300SCP (old designation HHR300SCP)) costed me 25 Euro and most commercially available replacement-batteries aren't far above that price-point. Doing this yourself and getting more accustomed with my spotwelder... that's something no commercial battery will ever replace.

The Metabo BZ 12 SP cordless drill

When I bought my Metabo BZ 12 SP drill back in 2006 or so, it came with the (back then) commonly available nickel-cadmium batteries (6.25473). Nickel-metalhydride batteries were available already but rather pricey and as my batteries were fine, there also was no need of replacement.

When I bought my Metabo BZ 12 SP drill back in 2006 or so, it came with the (back then) commonly available nickel-cadmium batteries (6.25473). Nickel-metalhydride batteries were available already but rather pricey and as my batteries were fine, there also was no need of replacement.

After about 10 years the capacity started to degrade noticeably and I bought a new machine. The old one went to my dad. The machine was still in good shape and as he didn't use it as much as I did, he could live with the by then limited capacity of the batteries.

Until February 2021, when one of the batteries really was worn beyond usable limits and only worked for about a minute straight after charging.

Could I fix that? By now, I had a spotwelder at hand and replacing the cells would be quite easy...

Batteries done: let's open them up!

I already placed an order at Nkon.nl and I found out they also had good quality cells (Panasonic) at hand for these purposes.

First of all the size (sub-C) is slightly abnormal, more importantly, not every sub-C cell can take the abuse cordless drills unleash on them: Current can easily shoot up to 8 to 10 times nominal when the motor stalls! This is why you need high-drain cells like the ones used.

With the cells in I opened up the defective battery. You will find the screws at the bottom and 1 screw is, to prevent the average consumer from opening it up, closed of with a small plastic cover. A 2 mm drillbit will eat its way in, so you can pull it out easily. I did find melted pins in other versions. Drilling those out is the only option.

With the cells in I opened up the defective battery. You will find the screws at the bottom and 1 screw is, to prevent the average consumer from opening it up, closed of with a small plastic cover. A 2 mm drillbit will eat its way in, so you can pull it out easily. I did find melted pins in other versions. Drilling those out is the only option.

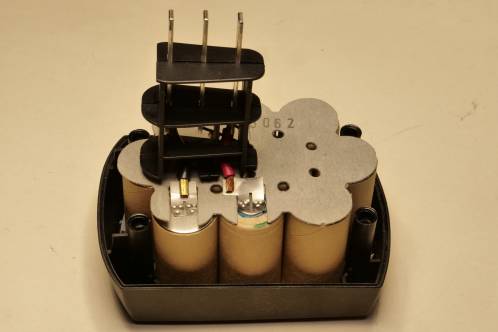

The cell-connections and strip-connectors is shielded with a very sturdy type of cardboard with a sticky side. The temperature sensor has its wires tucked away via one of the holes in the piece of paper.

The cell-connections and strip-connectors is shielded with a very sturdy type of cardboard with a sticky side. The temperature sensor has its wires tucked away via one of the holes in the piece of paper.

Removal therefor is rather hard and because I wanted to weld the connector-pins to the drill the last (So I would not have to fiddle with them with a new, highly-charged battery underneath me) I had to remove the cardboard first.

To make that slightly easier, I can recommend cutting a slit in the paper where the red line is.

It should go without saying that this is a dangerous operation when the cells are still in a rather good shape!

After cutting the slit, you can easily pull the carton down (in the picture).

Spotwelding the new cells and contacts

With the old cells near me I could easily see in which order the new cells had to be placed and which connections I would have to make. The nickel-strip is 0.2 millimeter thick and 10 mm wide, just like the original. The only thing that differs is the missing slit: strip with a slot between the spotwelding-points was something I could not obtain.

With the old cells near me I could easily see in which order the new cells had to be placed and which connections I would have to make. The nickel-strip is 0.2 millimeter thick and 10 mm wide, just like the original. The only thing that differs is the missing slit: strip with a slot between the spotwelding-points was something I could not obtain.

Every cell was first carefully abraided with some sanding paper (1600 grit), just like every surface of nickel to be spotwelded. Both surfaces were then cleaned with alcohol.

I used a few elastic bands to keep the cells together. With them in place, spotwelding was a piece of cake. kWeld-setting: 40 joule. Start with spotwelding on every negative terminal first. Positioning the strip is far easier there then on the positive terminal.

Ofcourse, the pack was then turned around to get all the necessary connections done there.

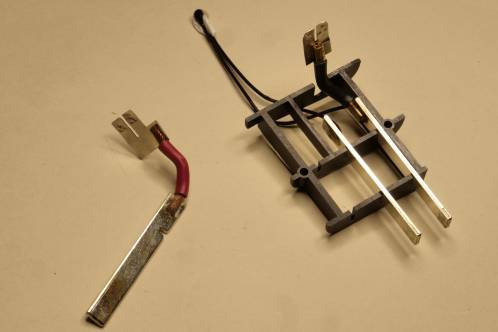

The only thing I recycled were the spotweld-contacts with mounted wires to the contacts that mate with the machine. This because the wires are welded ultrasonically and I would not be able to do that as neat and reliable as the original.

The only thing I recycled were the spotweld-contacts with mounted wires to the contacts that mate with the machine. This because the wires are welded ultrasonically and I would not be able to do that as neat and reliable as the original.

Using a Stanley-blade, I carefully separated these from their cells.

This is, (of course) a risky procedure, as the blade can cause a short! With my completely dead cells, that's not such a problem, when your cells are in better shape you don't want to think about it!

Make sure the contacts are nicely tucked away in the plastic holder and you completely assemble it first. If necessary, put a tie-wrap or elastic band around it. During spotwelding, you will be working with a fully charged battery. If you cause a short, you'll be sorry!

First weld the positive connection to the pack: this one needs to be aligned almost exactly centered with the only remaining positive terminal and automatically aligns the negative connection.

Check the voltage (around 13 Volt) when you're done. A drop of acrylate sealant fixes the temperature-sensor in place.

Attention! I have no idea if this is a special heat-conducting kind of sealant. All is done on your own risk!

Final work

After having the cement harden for 24 hours, the newly assembled pack is ready to be put together again. After placing the carton, the housing was screwed together.

After having the cement harden for 24 hours, the newly assembled pack is ready to be put together again. After placing the carton, the housing was screwed together.

The Metabo BZ 12 SP now has a new battery and can live on for a while. Even better is that the capacity has increased and has more than doubled (from 1,4 Ah to 3 Ah), so the machine sees longer runtimes, although charging will also take longer. The bad cells will be disposed off properly when the occasion arises.

I'll keep you posted how long this battery will last. (written on 28-03-2021).

But... But... What about lithium-ion?

Youtube features a lot of videos of people recelling batteries with lithium-cells, sometimes including extremely dangerous solutions to recharge them.

Aside from the danger and the problems of fitting these cells inside the battery-housing, there's also a practical issue: the AC 30 charger just can't charge lithium-cells. That makes for an easy choice.